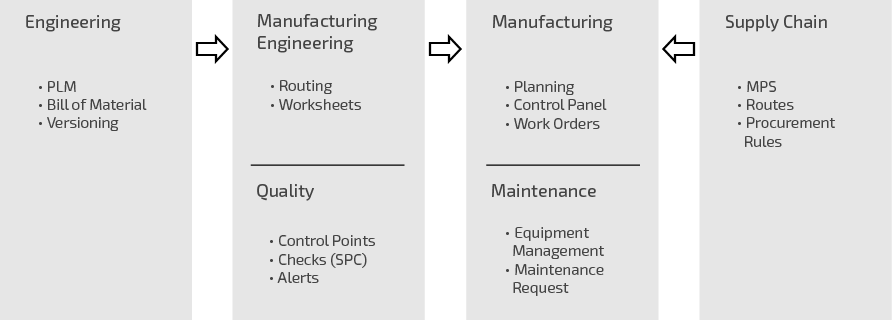

Odoo MRP (Manufacturing Resource Planning)

"From shop floors to marketplaces around the world."

Odoo Manufacturing Overview and Benefits

"Odoo helps industrial manufacturers to design, plan, build, deliver, and service products throughout their lifecycle. "Odoo Manufacturing helps you in scheduling, planning, checking the availability of raw materials and processing manufacturing orders. With the work center control panel, put tablets on the shop floor to control all your work orders in real-time and allow workers to trigger maintenance operations, feedback loops, quality issues, etc.

Fast-track time to market, gain new production efficiencies, and lower costs with Odoo

manufacturing software and Industrial Internet of Things (IoT) solutions.

Optional routing

Create new routings for work orders in order to sequence

your production depending on the routing used.

Product as Kits

Using the Kit feature, your salesperson will be able to

sell products that will be delivered as a set of components to

assemble.

Shop floor

automation

Capture data in

real-time from your equipment using the API

Manage semi-finished products

In

Odoo, you can use subassembly products to simplify a complex Bill of Materials or to

represent your manufacturing flow more accurately. A subassembly product is a

manufactured product that is used as a component to make another

one.

Using an alternative Work Center

For

many manufacturing companies, a common issue is to have to manufacture, at the same

time, several products usually produced at the same work center. If in practice,

employees can manufacture the goods at another work center, it is not that

simple.

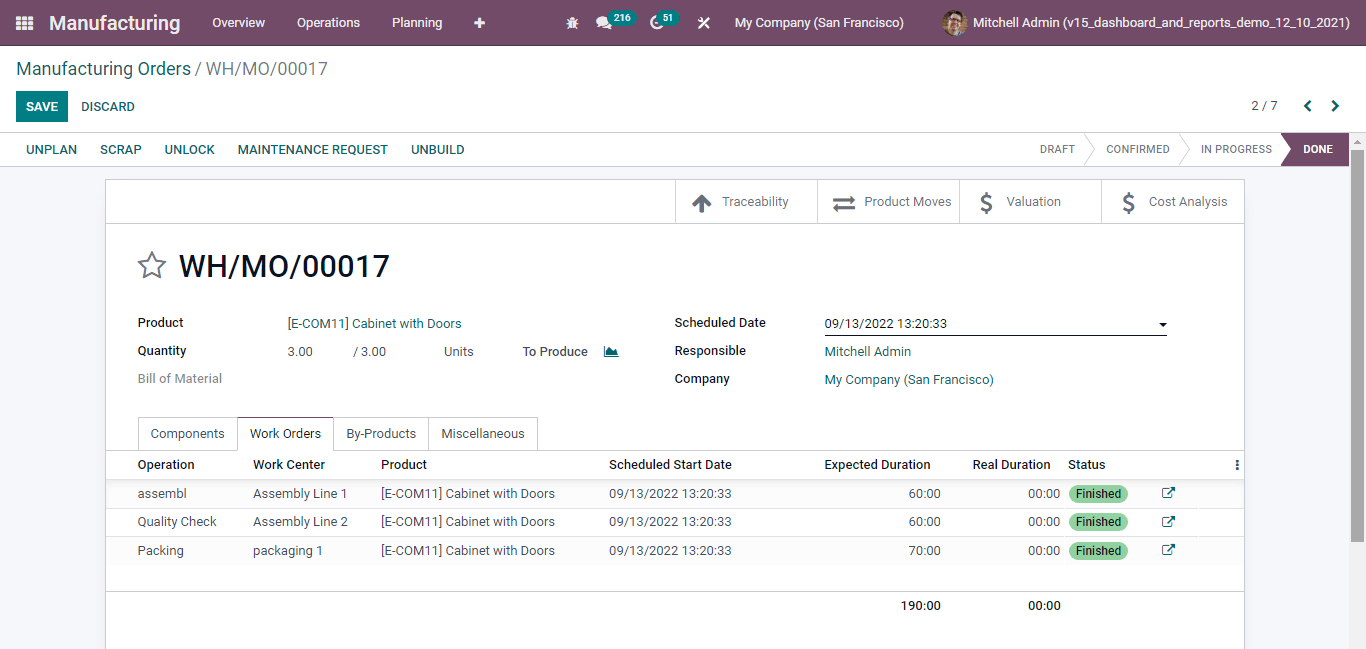

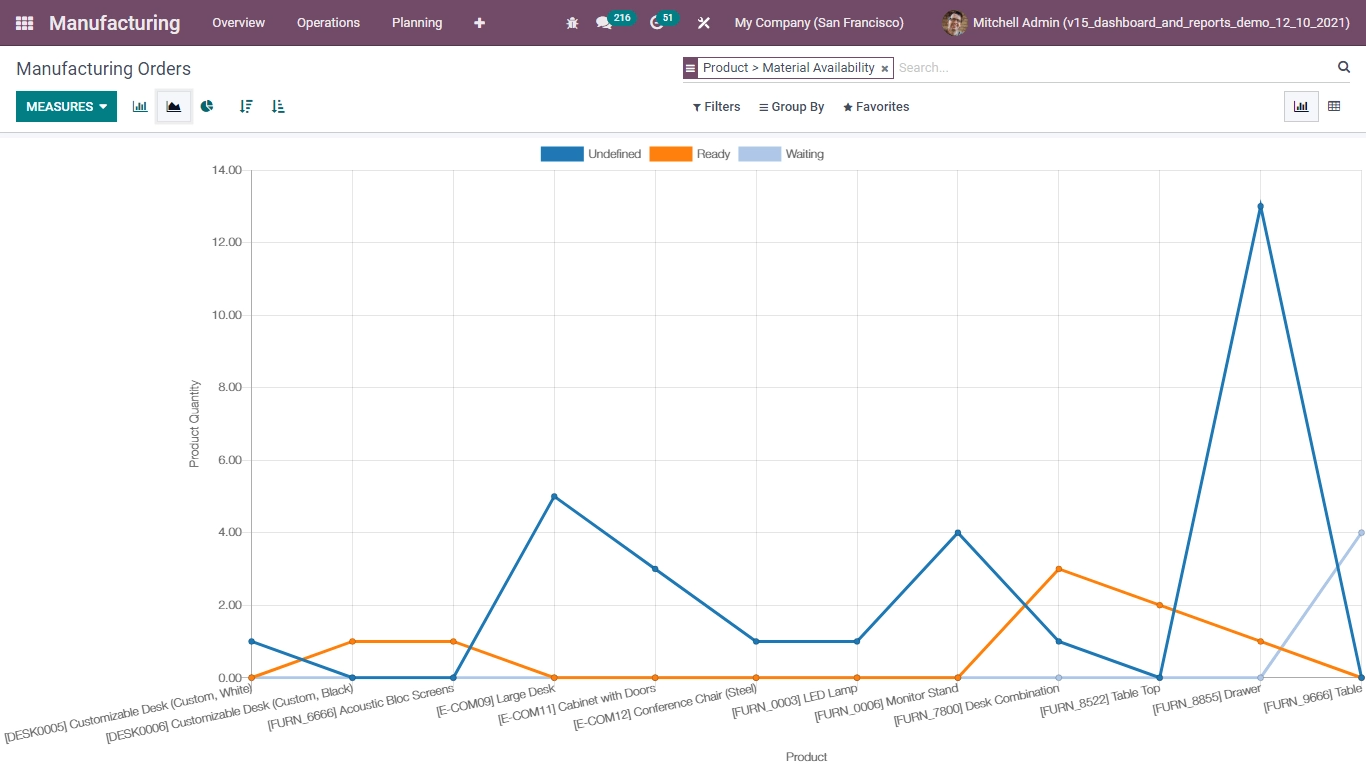

Odoo Manufacturing Orders

"Manage your products into assembly lines or manual assembly."

Editable MOs

You are now able to consume other products despite what was initially planned and edit MOs once they are done.

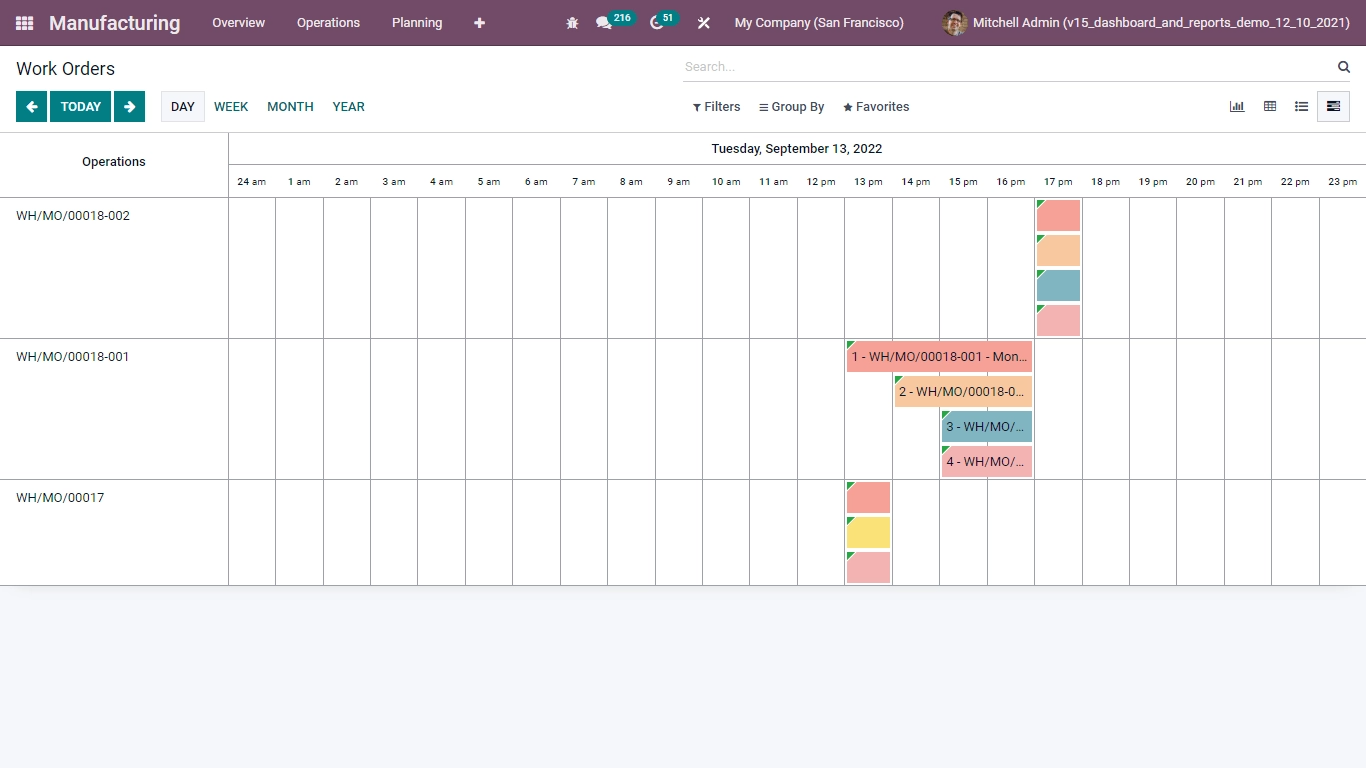

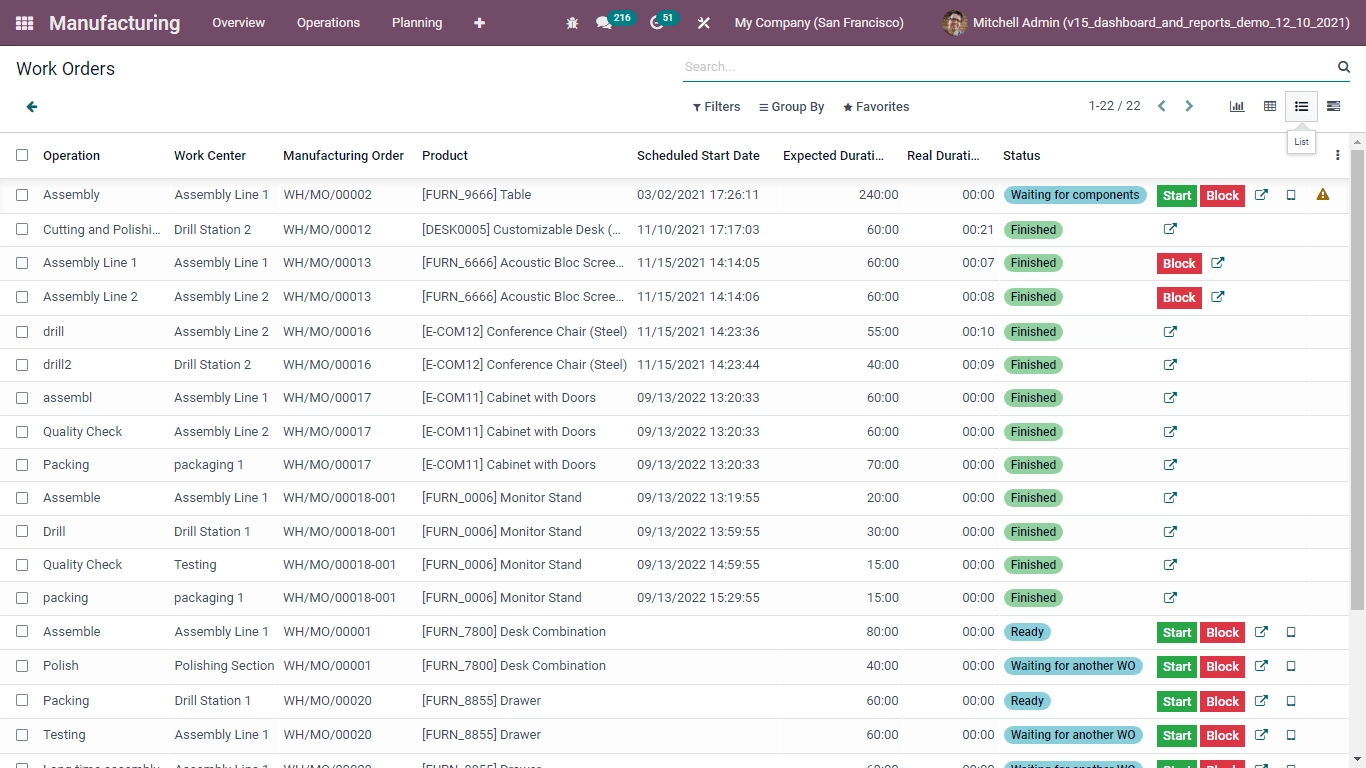

Odoo Work Center Control Panel

“Odoo Manufacturing module provide you to separate platform to

configure and manage your products and products variants as well."

Work center is an organization unit where manufacturing activities are performed. In other words, Work Centers are the master data which represent real machines, Production Lines, Assembly Work Center, etc. Manufacturing activity or Operations are carried out at the Work Center.

-

Register and record productions Integrate Quality checks

-

In process Alerts

-

Record Serial/lot number

-

Trace Timeline

-

Scheduling

-

Production Costing

-

Capacity Planning

-

Scrap products

-

Work center worksheet with instructions for the operator

-

Define multiple steps in a work order

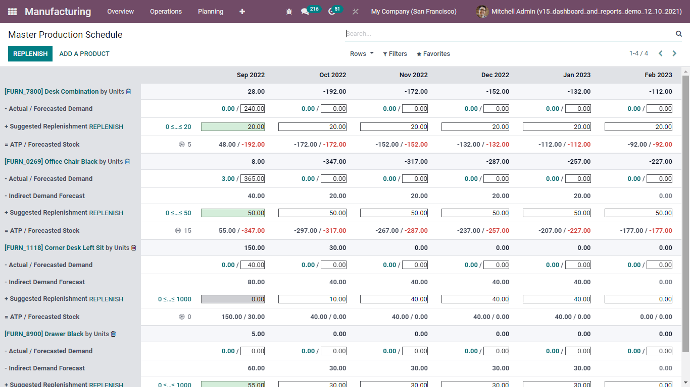

Odoo Master Production Schedule - MPS (Optimize Inventory Level)

“Ensures the right material, at the right time, at the right place and in the right quantity without the safety net of inventory."

Use make-to-order rules, minimum stock rules or the master production schedule to automate procurements. Let the scheduler compute everything for you. Use routes, constraints and lead time to optimize inventory level and avoid shortages.

-

Schedule and Plan Manufacturing

-

Organize work orders

-

MRP Scheduler to schedule your work at each work center

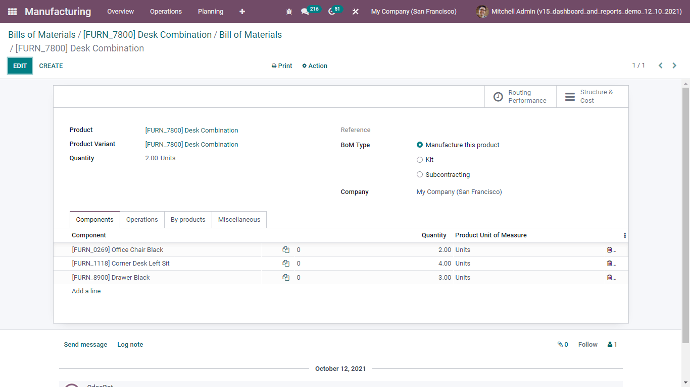

Odoo MRP BOM

“The whole manufacturing cycle starts with a BOM.”

A Bill of Materials is a document defining the quantity of each component required to manufacture a finished product which includes the routing & individual steps of the manufacturing process.

With Odoo, you can link multiple BoMs to each product and use it to describe multiple variants of them. Each BoM will, yet, be associated with one product only.

-

Track the availability of the items

-

Set / create Multi levels of BOM

-

Phantom BOM for selling products ( in kits)

Odoo Barcode

“Speed up manufacturing operations at every step."

Whether you use lots, serial numbers or unidentified products, you can use barcodes. start/pause/stop stopwatch, trigger a maintenance request, move to the next step, etc.

-

Reception Control

-

Picking

-

Packing

-

Work orders

Odoo Product Lifecycle Management-PLM

"Track versions of products and ECO's along with documents."

-

Merge different ECO's corresponding to the same BoM.

-

Manage Engineering Changes

-

Real-time communication across multiple departments & track changes with a great kanban process for ECOs.

-

Integrated Document Management for drawings, worksheets, and quality documents.

-

Smart versioning with efficient and merge.

-

With Odoo PLM, you can work and track changes on multiple versions of the same BoM in parallel and apply only the differences to manage multiple changes.

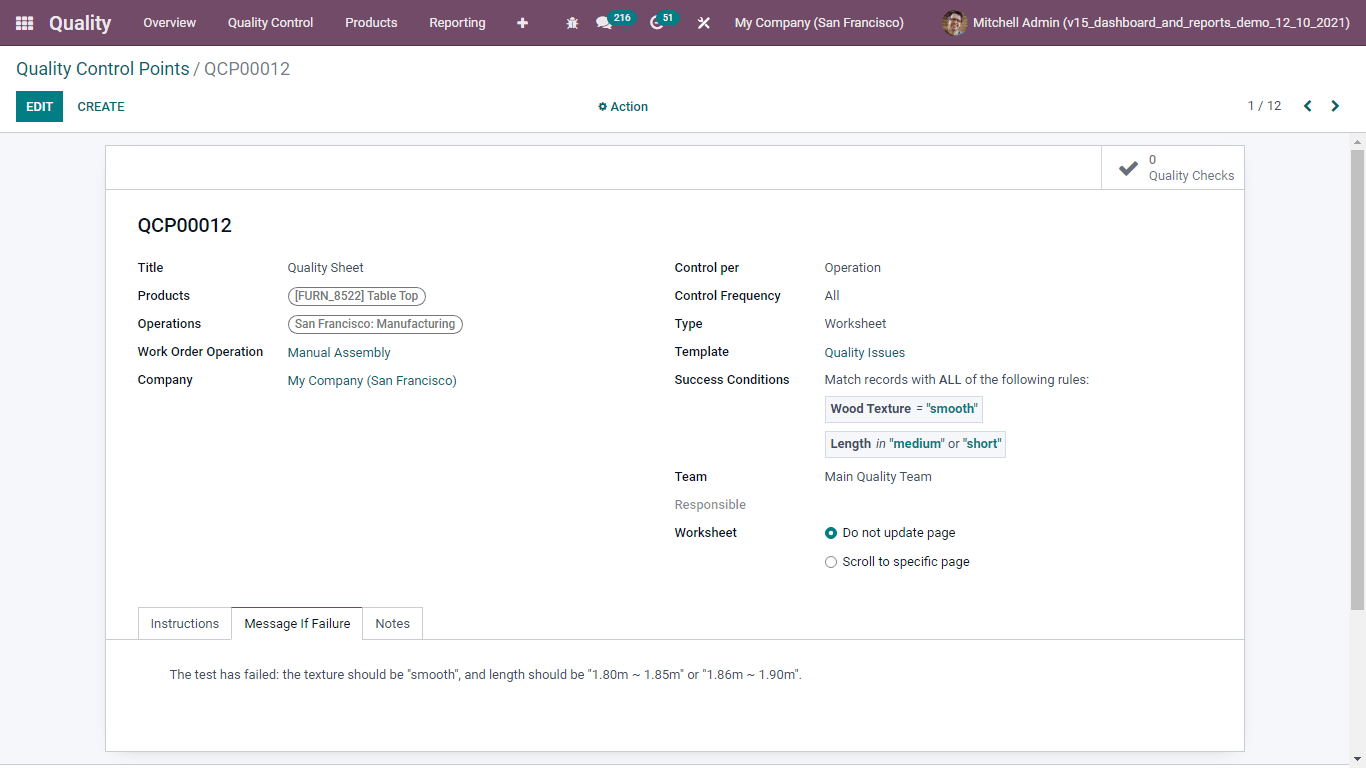

Odoo MRP Quality

“Fully Integrated with Inventory and Manufacturing operations."

-

Define quality control plans to trigger quality checks at specific inventory operations (receiving and final inspection) or manufacturing operations (in-process inspection).

-

Control Points: Route products to dedicated quality zones to perform advanced checks.

-

Quality checks and alerts are fully integrated with your manufacturing and inventory operations.

-

Workers can trigger a quality alert right from the work center control panel, or from inventory operations.

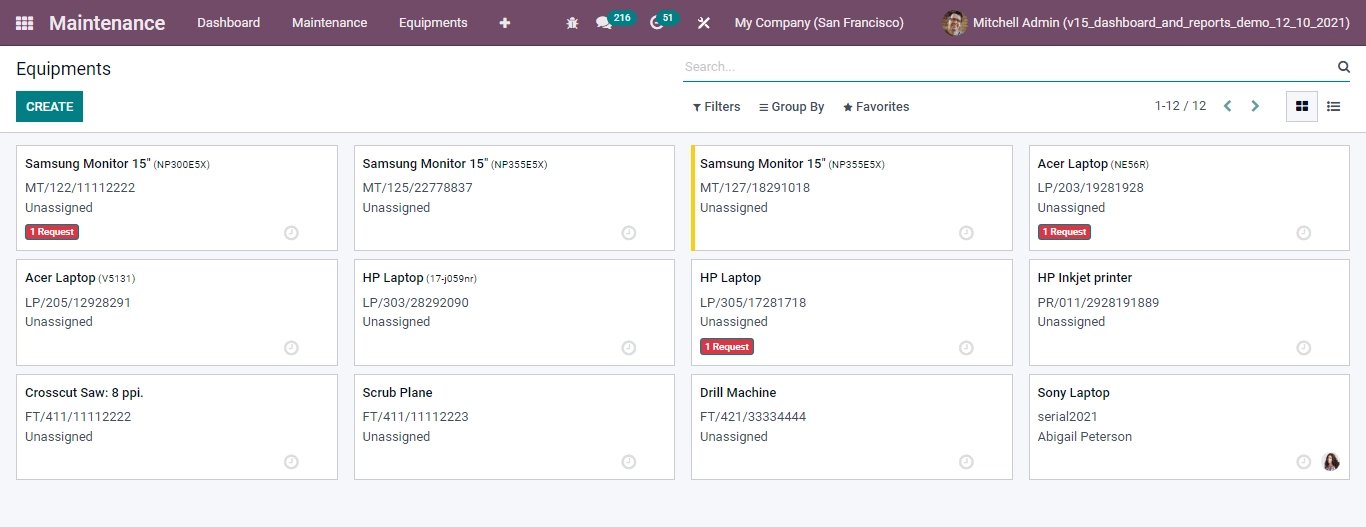

Odoo MRP Maintenance

“ Automate preventive maintenance to keep your line running."

Odoo computes standard statistics to help you plan preventive maintenance, including mean time between failure (MTBF), mean time to repair (MTTR), and expected next failure date, and lets you automate metrology and preventive maintenance scheduling.

-

Easily track and organize progress maintenance requests with great kanban and calendar views.

-

Use the fast and easy drag-and-drop maintenance calendar interface to organize and plan activities.

Corrective Maintenance

The manufacturing department can trigger maintenance requests directly from their work center control panel. When your maintenance team acts, the right people will be updated in real time.

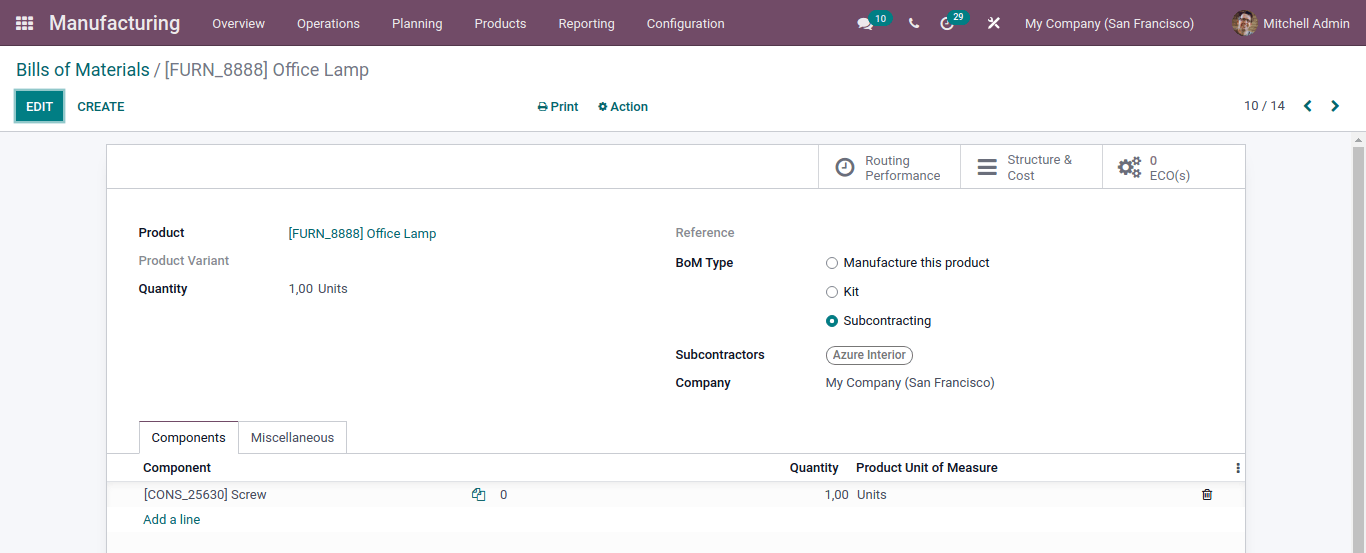

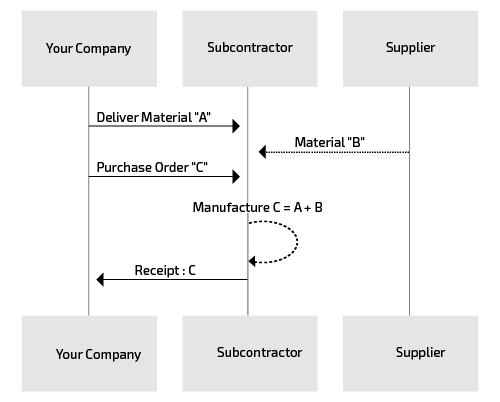

Subcontract your Manufacturing

“You require the subcontracting process in Odoo when a

company outsources parts of its manufacturing to subcontractors."

Outsourcing a portion of some or all your company’s manufacturing needs is not easy. To make it work right, you have to:

-

Manage the inventory of raw materials at your subcontractor

-

Ship new materials to your subcontractors based on your forecasted demand

-

Keep track of manufacturing operations done at the subcontractor location

-

Control incoming goods quality & subcontractors bills

Here is an example of subcontracting the manufacturing of “C”, which is produced out of raw materials “A” and “B”.

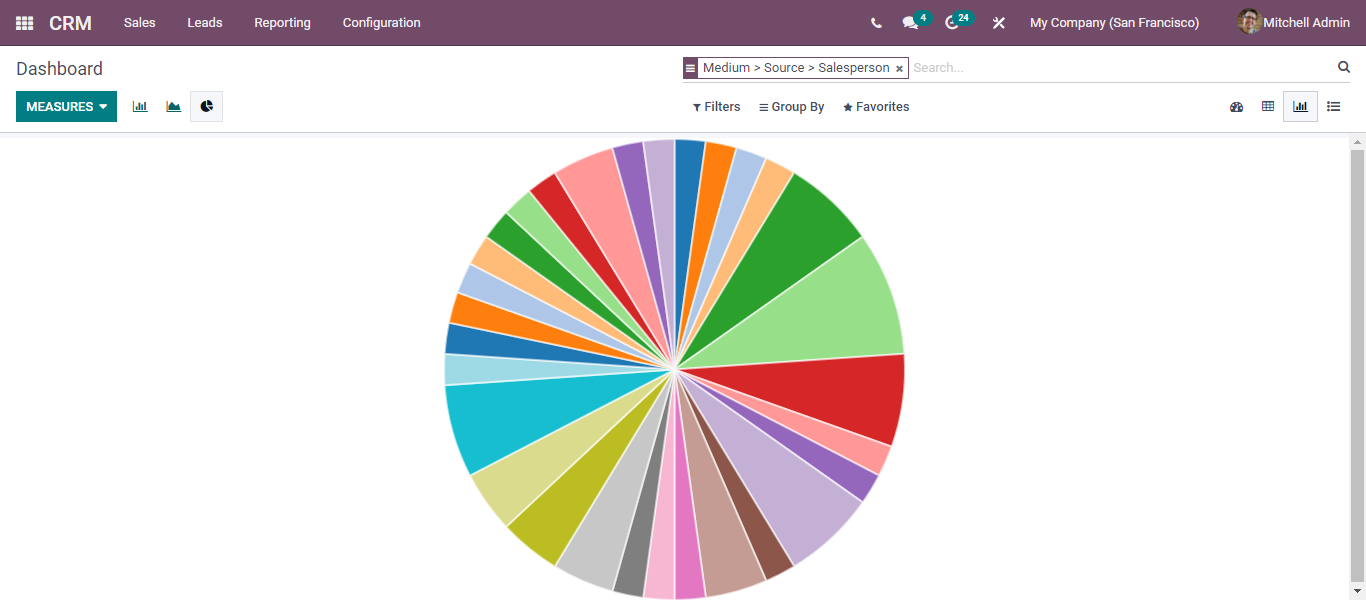

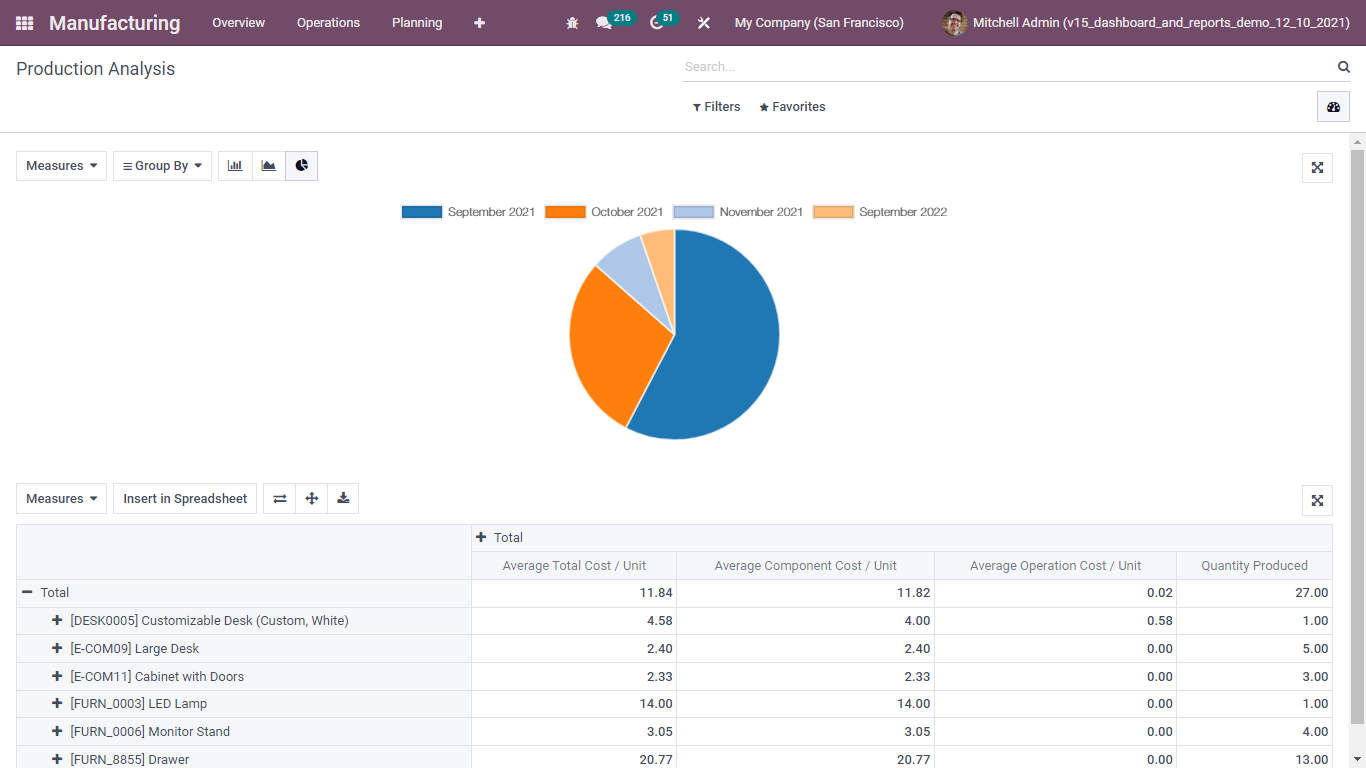

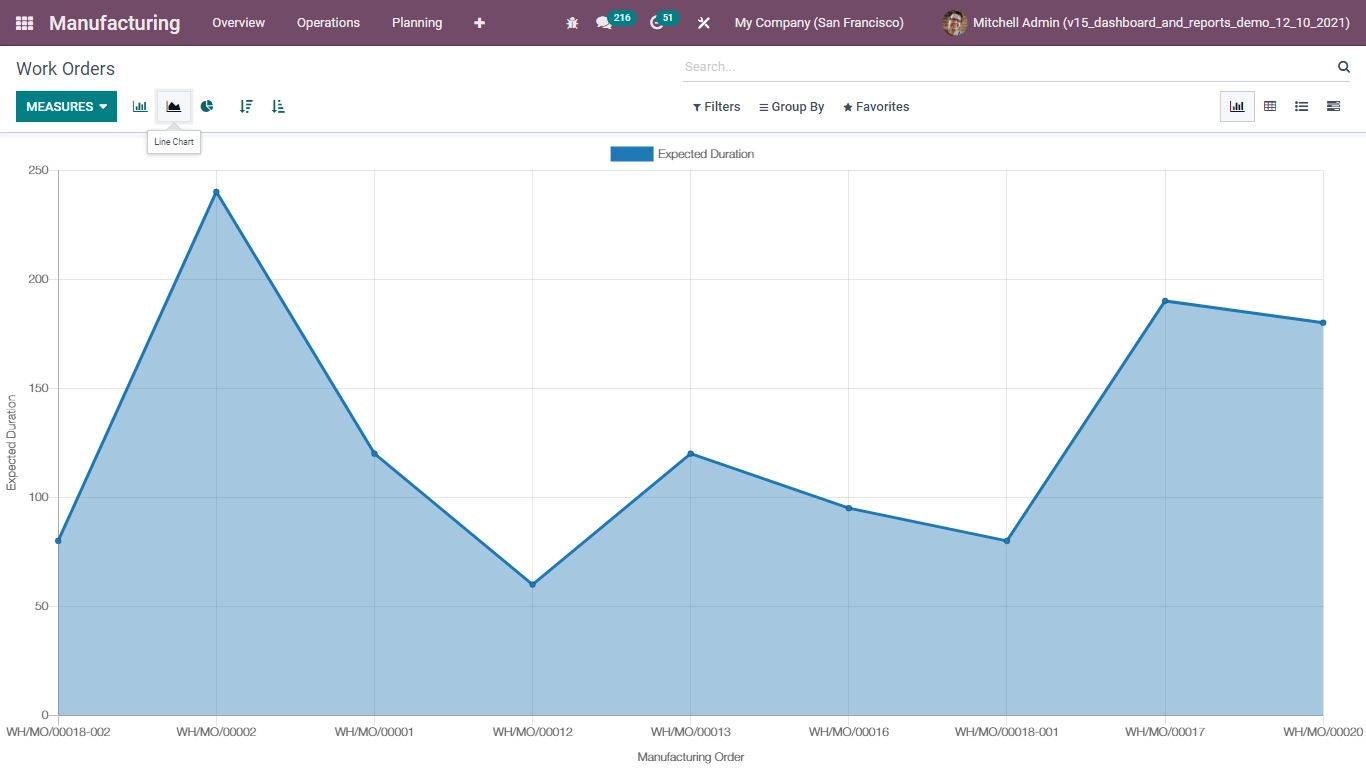

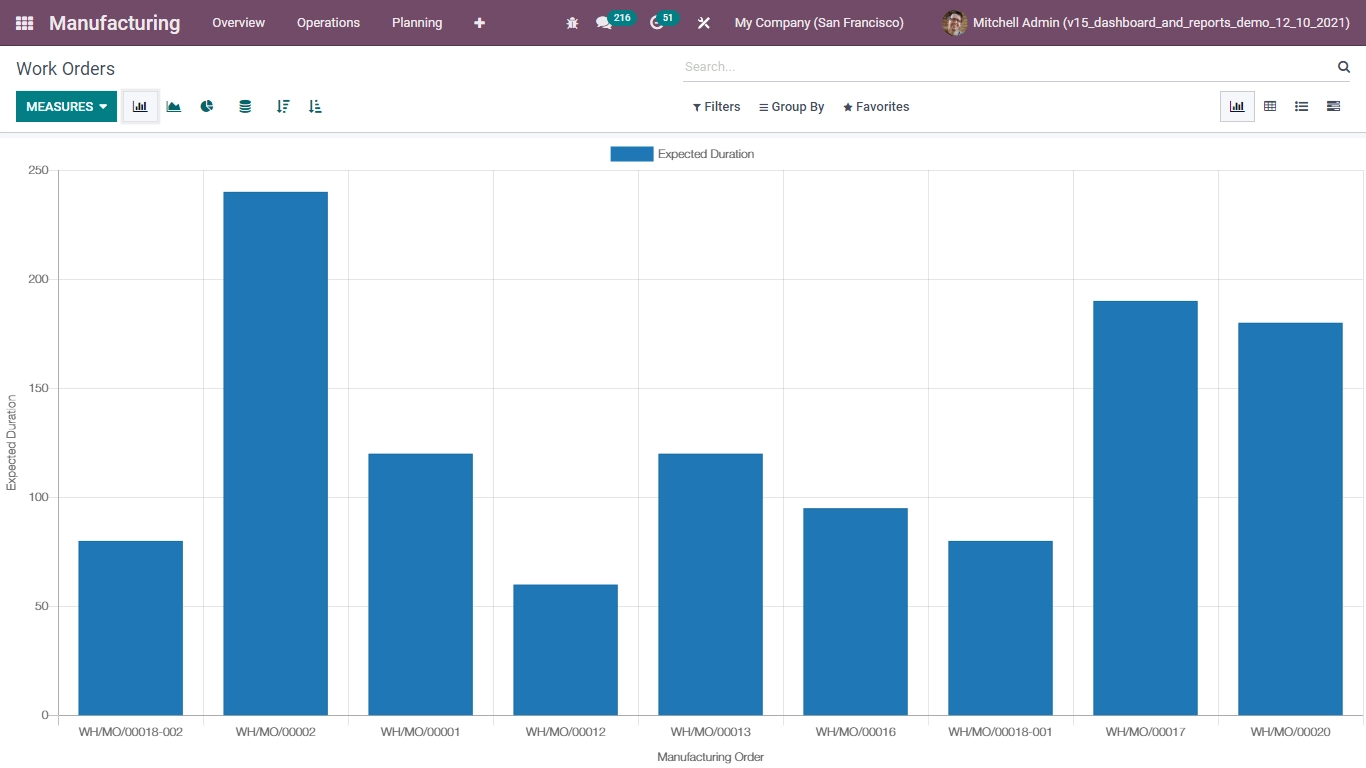

KPI and Reporting

“Dynamic reports on everything from costing to traceability, performance analysis, OEE."

Outsourcing a portion of some or all your company’s manufacturing

needs is not easy. To make it work right, you have to:

-

Different views of reports (PDF reports, XLS report, Chart views)

-

Real-Time OEE reports

-

Track KPIs with MTTR and MTBF

-

Design customize Dashboard

-

Dynamic reports

(traceability, performance analysis, OEE)

Dynamic reports (traceability, performance analysis, OEE)

-

Cost Analysis (cost of manufacturing based on labors & components)

-

Trace equipment with their effectiveness

Ready to supercharge your Businesses.

Jump-start your

implementation and drive ROI by collaborating with industry experts,

consultants, and

support engineers throughout your

journey.

Our highly trained representative are standing by, ready to help

- Installation & Configuration

- Training

- Customization

- Support